The South African customer’s cellophane wrapping machine order has been completed and will be shipped to South Africa in a week. The customer is a cigarette manufacturer in South Africa. After the cigarettes are packed in boxes, they are wrapped in cellophane and then 10 cigarette boxes are packed together.

According to the customer’s needs, we recommended him two models, 300A and 400. The combined use of the two machines can automatically complete the whole packaging process, making it easier to pack multiple boxes together.

Although the principles of these two models are basically the same, there are some differences:

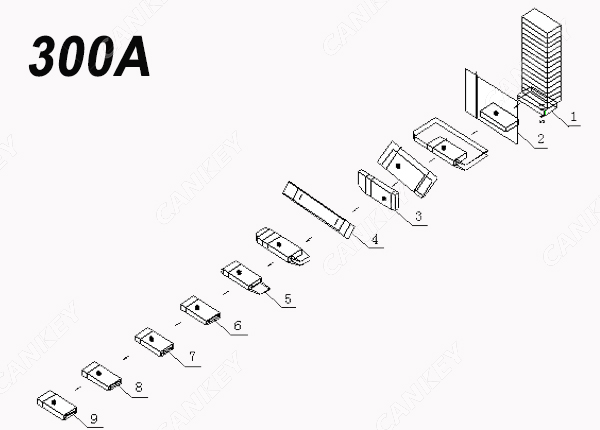

Model 300A:

Requirements for packaging materials: BOPP film, thickness 0.022~0.03mm

Working principle: After the box is manually put into the hopper, the vertical film is wrapped by the back pusher through the film cutting and then pushed into the corresponding cavity of the turret. When the turret rotates 90°, the folding film swing arm in the pre-sealed part moves to fold the wrapping film on one side from the outside to the inside. Then the pre-sealed swing arm folds the film on the other side from the outside to the inside and pre-seals it. After the pre-sealing is completed, the folded swing arm and the pre-sealed swing arm are retracted separately. When the turret rotates another 45°, the long-seal component will long-seal the box and then return it. When the turret rotates 45° again, the pusher of the discharging pusher pushes the packing box out of the turret mold cavity and enters the side seal part. The box is folded on both sides in turn, the top fold, the bottom fold, the front and the back side seals, propelled by the box behind, it enters the shaping part, and after shaping, it becomes a finished box and leaves the factory.

Wrapping process:

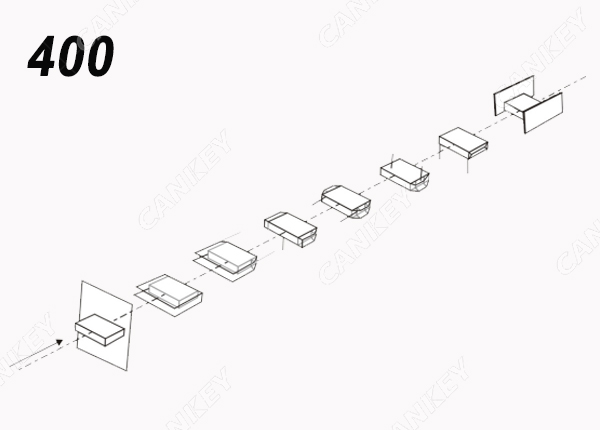

Model 400:

Requirements for packaging materials: Heat-sealed cellophane or OPP (BOPP) film with coating on both sides, generally 0.022~0.03mm thick.

Working principle: The mechanical transmission of 400 mainly adopts air cylinders, link rods, sprockets, chains and gears for transmission. After the box enters the workbench, the cut packaging film is wrapped around the box, the box moves forward, and the front-end folding plate makes the film produce the first crease. Fold the lower folding plate vertically, and fold the upper folding plate vertically, and heat-seal it to form, then the movable folding plate on the rear end produces a second crease on the end face, and folds the upper end face, and then folds the lower end. Finally, heat sealing on both sides is completed.

Wrapping process:

If you want to get more details about both model, please contact us info@cankeytech.com