Description

This box wrapping machine can be used for different types of boxes, such as gum boxes, sweet boxes, chocolate boxes, etc.

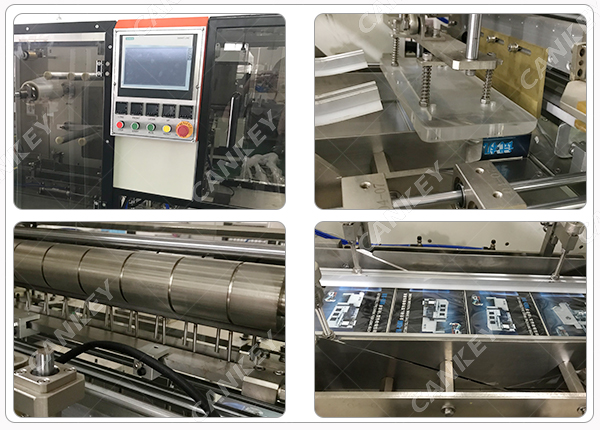

There is a new trend in wrapping sweet boxes with transparent film, which has a packaging effect similar to that of cigarettes. The entire packaging process is completed after film cutting, folding, end sealing, corner folding, side sealing, shaping, and output.

Gum Box Wrapping Machine Features:

- High production efficiency and degree of automation, can achieve continuous automatic production, and can achieve linkage and balanced production with the front-end cartoning machine.

- Choose BOPP or PVC film as packaging material, low cost.

- Reduced production costs and corresponding administrative costs due to less labor required.

- The packaged gum box has beautiful appearance and high grade, which is conducive to improving the product image.

- The gum box wrapped by the transparent film has good moisture resistance, which is convenient for transportation and storage, and is conducive to the storage of the gum.

Sweet Box Packing Machine Maintenance:

- Perform a complete maintenance of the surface every three months.

- After each use, the surface of the sweet box packing machine should be cleaned and covered tightly to prevent dust pollution.

- It is necessary to ensure that the machine is placed smoothly to ensure that the equipment can operate safely and normally.

- Select skilled operators to operate and use to prevent man-made damage.

- Regular maintenance should be carried out to check all possible hidden dangers.

- In the process of using, it is strictly forbidden to put your hands directly on the high temperature part of the machine, so as not to hurt your hands.

- After the machine is used, clean up the sundries on the machine to prepare for the next use.

Packaging Material:

The gum box wrapping machine’s packaging material is mainly BOPP film.

BOPP film, also known as biaxially oriented polypropylene cigarette film, is co-extruded and stretched from a variety of polypropylene functional materials. At present, domestic manufacturers generally use three-layer (A/B/C) co-extrusion technology to obtain high-performance BOPP films by biaxial stretching. With high transparency and gloss, the material is non-toxic, the molecular structure is stable, and it has a certain barrier function to odor and moisture.

Technical Parameter:

| Model |

CK-BTB-400 |

| Packaging material |

film and gold tear tape |

| Packing speed |

10-25 boxes/min |

| Max.package size |

(L)300*(W)200*(H)100mm |

| Power |

220V 50Hz 5.5kw |

| Machine weight |

1250kg |

| Machine dimensions |

(L)2380*(W)1050*(H)1680mm |