Description

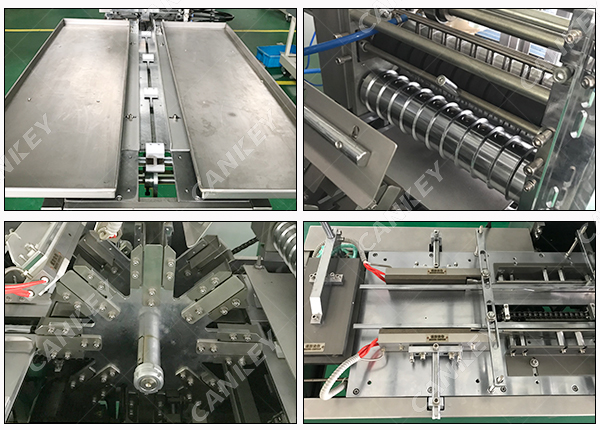

The cellophane wrapper machine uses BOPP film as the packaging material. It consists of a control system, a power mechanism, a transmission mechanism, and a fuselage. Stable performance, simple operation, convenient maintenance, firm and beautiful sealing, and high degree of automation. After the product is packaged, it can play the role of anti-counterfeiting, moisture-proof and dust-proof.

Cellophane Wrapper Machine Principle:

The box is transported forward through the inlet conveyor, and the servo motor controls the packaging film out of the film, and the film is cut into the length that meets the product packaging requirements by the cutter. The drive mechanism pushes the film together with the product to the feed pusher. The propeller rotates continuously at a certain speed, and during the rotation process, film wrapping, folding and single-side heat sealing are realized successively. The feeding pusher then sends the product to the exit conveyor, and the two ends are folded and heat-sealed while being conveyed forward.

Cellophane Wrapper Machine Features:

- Adopt multi-functional digital display inverter electrical components, stable and reliable operation.

- Stepless speed regulation of the inverter is adopted, which greatly reduces the transmission mechanism, improves the stability and reliability, and reduces the noise.

- Instant heat sealing, almost no effect on pharmaceutical products.

- Adopt sprocket drive, reasonable structure, simple operation and convenient maintenance.

- More energy saving than heat shrink packaging machine.

- Optional PLC man-machine interface control to ensure equipment stability.

The Role of Tear Tape:

The tear tape with the logo is pasted with the transparent film by self-adhesive, and has two main functions of anti-counterfeiting and easy unpacking.

- Anti-counterfeiting function. Because the tear tape can be printed with various corporate logos or names with graphic or laser holographic anti-counterfeiting signs, it can carry laser anti-counterfeiting, phosphorescence (fluorescence will appear under ultraviolet light)

- Easy-to-open function. Because of the easy-to-pull opening, it can be unpacked with a gentle pull.

Cellophane Wrapper Machine Application:

Mainly used for the outer packaging of carton products. It is widely used in the bopp film packaging of various single-piece small box-type items in the industries of medicine, tobacco, daily necessities, condoms, health products, food, cosmetics, stationery and other industries.

Data:

| Model |

BTB-300C |

| Packaging material |

film and gold tear tape |

| Packing speed |

40~80 boxes/min |

| Max.package size |

(L)240*(W)120*(H)60mm |

| Power |

220V 50Hz 5kw |

| Machine weight |

600kg |

| Machine dimensions |

(L)3000*(W)800*(H)1500mm |