Description

Cellophane wrap is currently the most commonly used packaging method for cigarette packs. It can not only maintain the freshness of cigarettes, but also extend the shelf life, the wrapping effect is flat, which can fully show the appearance and pattern of the cigarette pack.

The packaging steps of cigarettes are:

- Pack a fixed number of cigarettes into a pack;

- Wrap a single pack with cellophane film;

- Divide 5 or 10packs into a group;

- Assemble each into a carton, some packaging processes do not have this step, go directly to step 5;

- Wrap the carton with cellophane film.

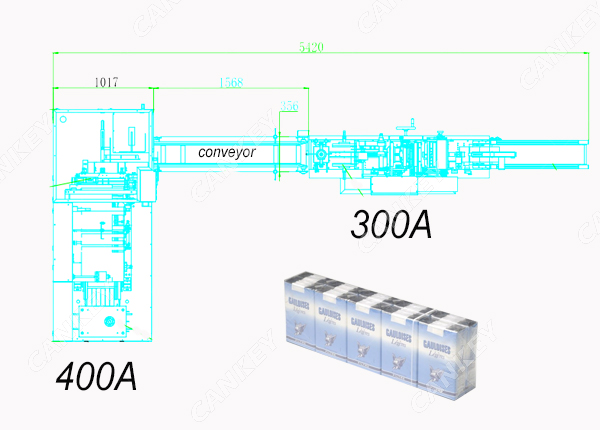

This article mainly introduces the 300A cigarette pack cellophane wrapping machine, which mainly completes step 2; step 4 mainly uses the 10 packs cigarette box wrapping machine to complete. These two models can be used in combination to form an automatic packaging line, for example:

Cigarette Pack Cellophane Wrapping Machine Features:

The work of the machine is completed by a series of cams inside the machine to drive various connecting rods and components. Adopt multifunctional digital display frequency conversion stepless speed regulation; PLC programming control technology; automatically feeding the box, automatically count, touch display to realize man-machine interface, pneumatic drop film; It can use in conjunction with other production lines.

- The service life of film cutter: up to 2 years or more, no need to sharpen the blade.

- Connection automation: direct conveyor belt docking connection.

- Cutter mounting frame: lifting double arm support by hand.

- Easy to maintain: the cigarette pack cellophane wrapping machine space is large, each part has a distance of the female finger size, and no parts are disassembled or assembled for maintenance and locking of the parts.

- No loss of material: using up the cellophane film directly, separated from the paper tube.

- Safety protection: if the machine breaks down or the box is stuck, it will automatically detect, automatically stop, and automatically alarm.